Doğru Lazer Kesim Makine Seçimi Nasıl Olmalı? | 2023 Lazer Kaseim Makine Rehber

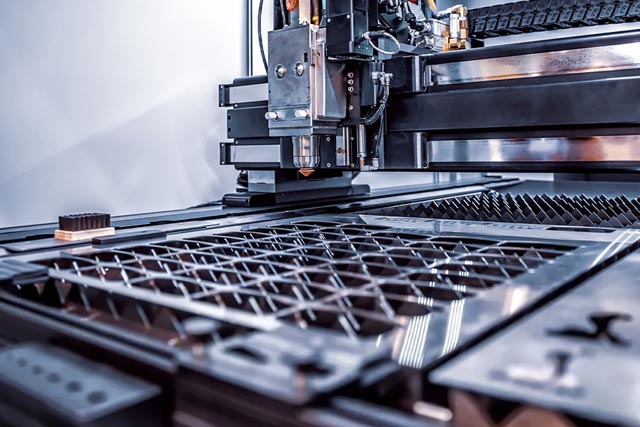

Teknolojik gelişmelerden bahsettiğimizde lazer teknolojisini gündeme getirmemek mümkün değil. Lazerin enerjiyi kullanma yeteneği oldukça şaşırtıcıdır. Lazer kesim makinesi, lazerin varlığını hissettirdiği en önemli alanların başında gelmektedir. Lazer, yüksek hassasiyeti ve doğruluğu nedeniyle diğer tüm teknolojilere en iyi alternatiftir. Lazer kesim makineleri hızlı ve verimlidir. Ayrıca mükemmel sonuçlar verirler.

Uygulama Nedir?

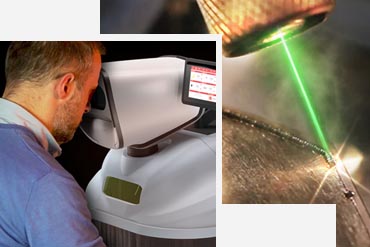

Lazer kesim, daha önce belirtildiği gibi çok çeşitli endüstrilerde kullanılmaktadır. Elektronik, tıp, savunma, otomotiv, sağlık ve tasarım endüstrileriyle başlayan zincir her geçen gün daha da ilerliyor. Lazer kesiciler yaygın olarak her türlü metali kesmek için kullanılmaktadır. Kesim işlemlerinde herhangi bir kısıtlama mevcut değildir. Çelik, alüminyum, pirinç, nikel ve demir bu aletle kolayca kesilebilir. Lazer teknolojisinin özel uygulaması özel bir ilgiyi hak ediyor. Neşter ve benzerleri gibi metal kesme aletleri ameliyathanelerde kullanımdan kaldırılıyor. İnsan dokuları ve hücrelerine artık bu teknoloji ile daha da güvenli olarak müdahale edilebiliyor.

Operasyonel olarak bu durum nokta atışı ve muazzam özen gerektiren yüksek riskli bir çabadır. Bununla birlikte, daha fazla risk almanın bazı avantajları vardır. Bir kaza sonucu veya zamanın tahribatı sonucu görme yetisini kaybeden hastalar retina düzeltme operasyonlarından yararlanabilirler. Hastanın görüşü, ameliyat sonrasında daha da iyi hale gelmektedir.

Lazer Kesime Yatırım Yapmamız Gerekiyor mu?

Bakır, alüminyum, pirinç ve paslanmaz çelik gibi metallerle çalışırken yüksek kaliteli sonuçlar veren bir kesme sistemine sahip olmak son derece önemlidir. Bir lazer kesici bu konuda size yardımcı olabilir. Yüksek kalite, düşük bakım, yüksek üretkenlik ve enerji verimliliği nedeniyle lazer kesiciler, kesme sistemi teknolojisinin zirvesinde yerini almaktadır.

Bir lazer kesiciye yatırım yapmak için en önemli 3 neden aşağıda olduğu gibidir:

- Düşük enerji tüketimi.

- Çalışanlar için azaltılmış ihtiyaç.

- Paradan tasarruf.

Başlıca kesme teknolojisi türleri nelerdir?

Aşağıda 3 ana lazer kesici tipinin listesi bulunmaktadır:

- CO2 Lazer Kesiciler

- Kristal Lazer Kesiciler

- Fiber Lazer Kesiciler

Lazer Kesim Makinesi Çeşitleri

-

CO2 Lazer Kesiciler

Karbondioksit (CO2) lazer kesim makineleri CO2 gazı ve helyum ve nitrojen gibi ek gazlardan oluşur. Lazer ışını, elektrik boşalmasıyla yüklenen bir tür gaz karışımı tarafından üretilir. Bu kesiciler 10.6 mm dalga boyuna sahiptir. Etkinliği ve düşük maliyetleri nedeniyle CO2 lazer kesiciler en yaygın olarak kullanılan kesicilerdir. Cam, plastik, deri, ahşap ve akrilik kullanılan malzemelerden bazılarıdır.

-

Kristal Lazer Kesiciler

İtriyum ortovanadat kristalleri Neodimyum ile katkılanır ve kristal lazer kesicilerde kullanılır. Bu kesicilerin dalga boyu CO2 lazer kesicilerinkinden daha kalın malzemeleri kesebilirler. Yüksek öncelik ve yoğunluk, daha kısa bir dalga boyu ile de kolaylaştırılır. Parçalarının aşınması bu kesicilerin yüksek güçte çalışmasının bir dezavantajıdır. Plastikler, metaller ve seramiklerin tümü kullanılabilecek malzemelere örnektir.

-

Fiber Lazer Kesiciler

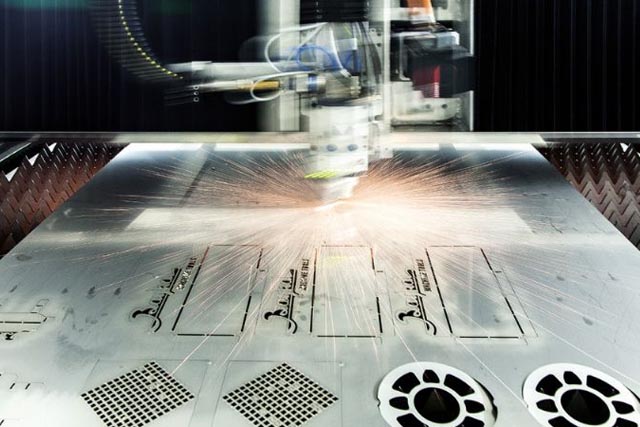

Bir tohum lazer, belirli optik fiberler tarafından güçlendirildiğinde ve büyütüldüğünde, sonuç bir fiber lazerdir. Katı hal lazerlerine yaygın olarak fiber lazer kesiciler denir. CO2 lazer kesicilere kıyasla, bu lazer kesici üç kat daha verimlidir ve sunduğu avantajlar daha fazladır. Fiber lazerler hem metallerle hem de organiklerle çalışabilir. Kristal lazer kesiciler gibi görünebilirler; ancak daha verimlidirler ve fiber lazerlerden daha az bakım gerektirirler. Metaller ve organik bileşikler, günümüzde kullanılan malzemelerin çoğunluğunu oluşturmaktadır.

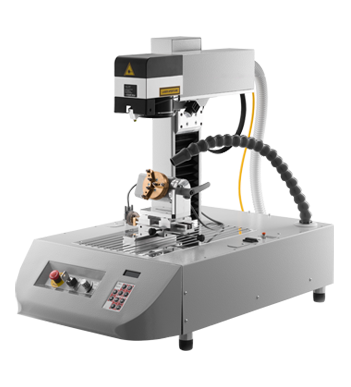

Kuyumculuk Sektöründe Kullanılan Lazer Kesim Makinelerinin Çeşitleri

Kullandıkları lazerlerin türüne göre çeşitli lazer kesim makineleri vardır. Sonuç olarak, kullanılan lazer tipi alt tabaka tipini ve kalınlığını belirler.

- CO2 Lazer Kesiciler

- Kristal Lazer Kesiciler

- Fiber Lazer Kesiciler

Lazer Kesim İşlemini Kontrol Etmek Ne Demektir?

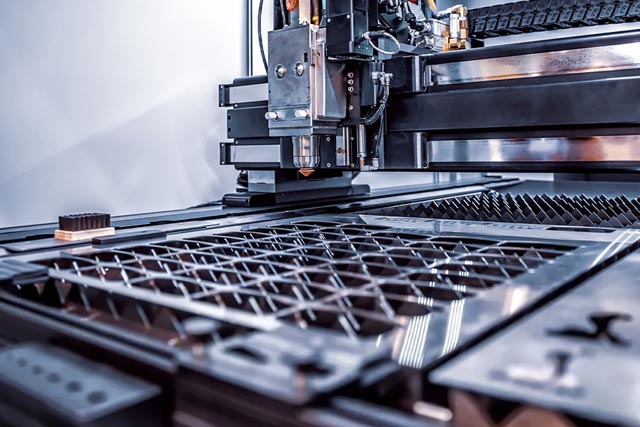

Lazer kesimde, optik ve CNC aracılığıyla ışın veya malzeme istenilen yöne yönlendirilen yüksek güçlü bir lazer kullanılır. Malzeme üzerinde kesilmesi istenen desenin bir CNC veya G kodu genellikle bir hareket kontrol sistemi tarafından okunur. Odaklanmış lazer ışınının yanmasına, erimesine veya buharlaşmasına izin verilsin ya da bir gaz akışı ile uzaklaştırılsın, yüksek kaliteli bir yüzey bitmiş kenar üretilir.

Lazer Kesim İle İlgili Başka Ne Düşünmelisiniz?

Bir lazer kesici seçmeden önce birkaç faktör hakkında dikkatlice düşünmek önemlidir. Bu yazımızda daha önce değindiğimiz CO2 lazerin kalitesi, maliyeti ve üzerine kesilip kazınabilecek malzemenin minimum kalınlığı önemli hususlardır.

- Ürün kalitesi

- Maliyet

- Malzemenin minimum kalınlığı

Emniyet

Hassas kesim ve kazıma için lazer kesiciler güçlü bir lazer kullanır. Lazer kesici kullanırken yangın ve potansiyel olarak zararlı veya rahatsız edici yanma yan ürünleri riski vardır. Lazer kesicinin yüksek güçlü lazeri cildi ve gözleri yakabileceğinden makine güvenli bir şekilde saklanmalıdır. Lazer kesim makinesi satın alırken "hava destekli" bir model aldığınızdan emin olmalısınız. Bu güvenlik önlemi, yangınları önlemede oldukça önemlidir. Ayrıca daha temiz kesimler yapılmasına yardımcı olur.

Güvenlik Değerlendirmesi:

- Asla tek başına çalıştırmayın.

- Daima uygun şekilde donatılmış bir yangın söndürücü bulundurun.

- Kir ve yanıcı maddeleri kesiciden uzak tutun.

- Lazer kesicinin içini temizleyin. Tepsiyi kullanım arasında kalıntı ve kalıntı açısından inceleyin.

- Lazer güvenlik özelliklerini asla devre dışı bırakmayın.

- Lazeri uygun kaplamalar ve kilitler olmadan çalıştırmayın.

- Lazer ışınına bakmayın.

- Optikleri doğrudan kullanmayın.

- Onaylanmış olan uygun malzemeleri kullanın. Lazerle oyulmuş, etiketlenmiş veya kesilmiş nesneler zararlı buharlar yayabilir.

Plazma Kesme Makinesini Ne Zaman Seçmelisiniz?

Sık sık 14 boyutta keserseniz, daha büyük bir bıçağa ihtiyacınız olacaktır. Düşük amper değerlerine sahip plazma kesiciler, daha kalın malzemeleri kesmek için daha uygundur. İnşaat ve kurtarma endüstrilerinde metal imalat işlemleri için plazma kesme yaygın olarak kullanılır. Tabela ve heykel ile iç mekan projeleri için dekoratif paneller, tasarımcılar ve sanatçılar tarafından en tipik kullanımdır.

Su Jeti Kesim Makinesini Ne Zaman Seçmelisiniz?

Su jeti ile kesme işlemi, tasarımcılara diğer kesme yöntemlerinden daha fazla seçenek sunar. Su jeti ile kesme kullanarak hemen hemen her malzemeden düzensiz şekiller keserken olağanüstü hassasiyet ve kenar kalitesi elde etmek mümkündür. Su jetleri artık eğrileri, düz kesimleri, iç delikleri kesebilir ve her zamankinden daha hızlı yazı yazabilir. Su jeti ile kesme, diğer kesme yöntemlerinin en yaygın dezavantajlarından ikisi olan ısı bozulmasını ve sertleştirilmiş kenarları önler. Karmaşık metal üretimi ve kesimden sonra ekstra işleme gerektiren ürünler bundan faydalanmaktadır.

Bir Oksi Asetilen Kesme Makinesini Ne Zaman Seçmelisiniz?

Oksi asetilen kesme işlemi, prosedürü açıklamak için kullanılan terminolojiye bağlı olarak oksijenli kesme, alevle kesme, oksijen yakma veya çelik yakma olarak da adlandırılır. Bu teknoloji yaklaşık olarak bir buçuk asırdır var. Merak edenler için, ana uygulamalarından biri bankaların kasalarını soymaktı. Oksijen yakıtla kesme ile çok çeşitli parçalar kesilebilir, ancak tüm metaller bu işleme iyi yanıt vermemektedir. Bu teknikten yalnızca karbon alaşımlı metaller (yumuşak çelik gibi) yararlanabilir. Bir kabuğun oluşmasını önlemek için oksitleri, ana metalin kendisinden daha düşük bir erime sıcaklığına sahiptir.

EDM Kesme Makinesini Ne Zaman Seçmelisiniz?

EDM kesme makinesi, prototiplerden büyük üretim çalışmalarına kadar her şey için kullanılabilse de, en yaygın olarak metal bileşenler ve aletler yapmak için kullanılır. Düşük kalıntı stres seviyeleri bu prosedür için ideal bir seçimdir.

Bıçak Kesme Makinesini Ne Zaman Seçmelisiniz?

Baskı endüstrisi, kağıt kesme bıçakları için en iyi malzeme ve en son açı kombinasyonunu araştırmak için çok zaman harcamıştır. Düz kesme makinelerinde, kesme kenarı için yüksek hız çeliği kullanımı önemli ölçüde azalmıştır ve sertliği nedeniyle semente karbür alaşımı artık birincil seçimdir. Kağıt türünün yanı sıra, tane yönü, ortam sıcaklığı ve nemi, sıkıştırma basıncı ve bir seferde kesilen yaprak sayısı da dahil olmak üzere birçok başka faktör kesme kenarının keskinliğini etkiler.

Makine Konumu ve Erişilebilirlik

Lazer kesiciler, çeşitli malzeme türlerini kesebilen, işaretleyebilen ve kazıyabilen çok amaçlı ekipmanlardır. Lazer kesiciler daha yaygın olarak erişilebilir hale gelmekte ve iş istasyonu modellerinden kapalı lazer kesicilere kadar çok çeşitli ayarlarda bulunabilmektedir.

Ekipmanı Çalıştırmanın Gerçek Maliyeti Nedir?

Lazer kesim makineleri söz konusu olduğunda, çalıştırmanın maliyeti nedir? Bir lazer kesim makinesini çalıştırmak şaşırtıcı derecede ekonomiktir. Bir saat boyunca, %50 güç çıkışına sahip 60 watt'lık bir cam CO2 lazeri 360 watt tüketir ve bu da yaklaşık 0,05$/0,07 €/0,05 £'a denk gelir. Bir lazer kesim ve oyma makinesinin fiyatı, müşteri için önemli bir husustur. Uygulamanız için en uygun maliyetli çözümü seçmek zor bir iş olabilir, ancak bu konuda endişelenmenize gerek yok AlexMakine’yi ziyaret edebilirsiniz.

Satın Alma İşlemini Finanse Edecek Miyim?

Bir lazer makinesi satın alırken, muhtemelen kendinize soracağınız ilk sorulardan biri, finansmanın mı yoksa nakit ödemenin mi en iyi seçenek olduğudur.

Bir lazer kesme makinesini finanse etmenin 5 avantajı:

- Herhangi bir önemli ekipman parçası için borç alarak tasarruf edebilirsiniz.

- Lazer kazıma ekipmanınız, doğru şekilde kullanırsanız zaman içinde kendini amorti edecektir.

- Satın alma işlemini finance ederken lazerin tüm maliyetini ve vergi amaçlı faiz ödemelerini düşmenize olanak tanır.

- Finansman çok çeşitli seçenekler sunar.

- Ekipman aldığınız sure boyunca ekipmanınızı istediğiniz an kolayca yükseltebilirsiniz.

Teslimat ve Kuruluma Neler Dahildir?

Maliyetli gecikmeleri önlemek veya projenin güvenliğinden ve bütünlüğünden ödün vermekten kaçınmak için, uygun lazer kesim makinesini teslim etmek ve kurmak, her düzeyde kapsamlı bilgi ve hassasiyet gerektirir.

Lazer kesim makinesi hizmetlerinin sağlanması ve kurulması:

- Firma olarak her türlü lazer makinesi teslim edilir ve kurulur. Bileşenleri yerinde üretmeye, teslim etmeye ve monte etmeye ek olarak, personelimiz bunu yapacak uzmanlığa sahiptir.

- Baştan sona tüm süreç boyunca tam memnuniyetiniz sağlanır.

- Alex Makina servis, makine teslimatı için fiyat teklifi almanıza yardımcı olabilir. Uzman ekibimiz, ürününüzün zamanında tamamlanmasını ve teslim edilmesini sağlayacaktır.

Satın Alma Kararını Kolaylaştırmak İçin Neler Yapılabilir?

Ürünün kalitesi, fiyatlandırması, makinelerin istenilen yerde bulunabilirliği ve daha fazlası tüketiciler tarafından dikkate alınmaktadır. Tüketicinin yaşı, mesleği, yaşam tarzı, kültürel ve mali durumu gibi özellikleri dikkate almak son derece önemlidir.

Doğru Satın Alma Nasıl Yapılır?

- İhtiyaç ve istek arasındaki farkı düşünün.

- Sorular sorun.

- Mevcut mali durumunuzu düşünün.

- Kullanım başına maliyet analizi yapın.

- Olasılıkları düşünün.

- Mümkün olduğu kadar çok bütçe ayırın.

Bu basit yönergeleri izleyerek akıllıca alışverişler yapabilirsiniz.

Doğru Marka Nasıl Seçilir?

Bir markanın kimliğinin önemli bir parçası, tüketicilerin ve diğer kilit kitlelerin o şirketle ilişkilendirdiği adıdır. Gerekli ürünlerinizi satın almak için marka görevlerine güven ve bilgiyle yaklaşmalısınız. Yanlış markayı seçmek, bir ürünü veya hizmeti deneme şansınız olmadan önce size pahalıya mal olabilir. Yeni bir ürün satın alıyor olsanız da olmasanız da, neyi temsil ettiğini ve hitap ettiğini anlatan bir marka seçmelisiniz. Alex Makine, seçmenize yardımcı olacak lazer kesim makinelerinin malzemelerini, niteliklerini ve özelliklerini bilmektedir. Her metal için yüksek kaliteli, işlevsel ürün hatlarına sahip bir tedarikçi seçmenizi öneririz. Bu en iyi seçenek olacaktır. Bir lazer kesim makinesi için alışveriş yaparken, ihtiyacınız olanı ve daha fazlasını aldığınızdan emin olmak için birçok model arasından seçim yapabilirsiniz.

En İyi Lazer Kesim Makinesini Nasıl Seçeriz?

Kişiye özel takı yapım süreçlerini iyi bilmelisiniz. Sizlere birçok lazer kesici türü sunuyoruz. Herhangi bir ürünü kullanmadan önce kalitesini kontrol etmenizi öneririz. Müşterilerimizi endüstri ve üretim iyileştirmelerinden haberdar etmek için her şeyi yapmaktayız. Mücevher üretiminizi ve işlemenizi optimize etmek için gelişmiş yazıcılara erişiminiz firmamız sayesinde olacaktır. Alex Makine olarak ihtiyaçlarınıza ve bütçenize uygun çözümler sunarak tasarruf etmenize yardımcı oluyoruz. Bu ürünlerin her birini toplu olarak sipariş verebilirsiniz.

SSS:

Bir lazer kesim makinesini nasıl seçerim?

Lazer kaynakları, yatak boyutları, lazer tüp gücü ve aksesuarlar gibi birçok değişken arasından seçim yapabilirsiniz. Makine seçimi çoğunlukla şu faktörden oluşur: Hangi malzemeyi ve kalınlığı kesmek/oymak istiyorsunuz? Bu, gereken lazerin tipine ve gücüne karar verecektir.

Parlak metaller için hangi lazer kesim en iyisidir?

Küçük nokta boyutları nedeniyle, fiber lazerler parlak metalleri kesmek için mükemmeldir.

Bir lazer kesici gravür makinesini nasıl seçerim?

Daha yüksek güç aralığına sahip CO2 lazer kesiciler ve gravür makineleri, metal olmayan malzemelerle çalışmak için idealdir. Metallerle, çelik veya alüminyum gibi yansıtıcı yüzeylerle çalışmanız gerekiyorsa, fiber lazer en iyi seçenektir.

Lazer kesici alırken nelere dikkat etmeliyim?

Bir lazer kesici satın alırken göz önünde bulundurulması gereken birçok husus vardır. Fiyat, kesilebilecek ve üzerlerine kazınabilecek malzemenin minimum derinliği ve tabii ki CO2 lazerin kalitesi önemli hususlardır.