Vacuum Casting For Jewelry: A Step-By-Step Guide

Jewelry casting is a method of creating jewelry that requires pouring liquid metal alloy into a mold. The Step-by-Step Guide is covered in this article, Vacuum Casting for Jewelry.

What is Vacuum Casting?

The vacuum is used to suck any liquid substance into the mold during the casting process. Vacuum casting is used when there is an issue with the mold, and it is being clogged with air. The method can also be used for complex features and undercut mold release processes. Fiber or reinforced wire are commonly utilized in the manufacturing of molds. The manufacturing method is frequently referred to as thermoforming since the plastic sheets are preheated before usage. Until they are soft and flexible, the ingredients are preheated in an automated vacuum casting machine.

Why Try Wax Casting?

It is a process used by artists to produce huge and tiny sculptures. A mold is made from a wax model of an item. The sculpture can be created by pouring molten metal into the mold. This approach has been employed in societies all around the world for thousands of years. Wax casting can help a jeweler shine through his creativity. Wax can be modeled in almost any imaginable shape. It is also easy to play with various textures and decorations.

Tools and Supplies for Vacuum Casting

1. Wax models or patterns

2. Wax sprue

3. Flasks and sprue bases

4. Investing.

5. The scale

6. Equipment for mixing

7. De-bubbling agent.

8. A burn-out oven equipped with a pyrometer.

9. The torch

10. Eye protection

11. Hand protection

12. The crucible

13. The stirring rod

14. The state of flux

15. A bucket of five gallons

16. Extinguisher for a fire

17. The casting machine is the last but not least.

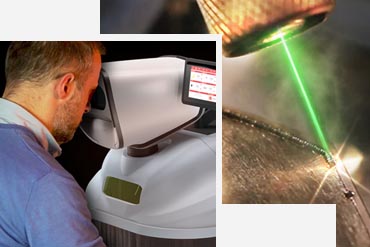

Vacuum Casting Machines

A vacuum casting machine fills the mold with metal weight and force. The molten metal is sucked into the mold by the use of a vacuum in an aspirator. The centrifuge machine must be securely attached to a high platform and enclosed by a security barrier. A metal washbasin or dryer drum clothes can be utilized. There are no openings in the barrier to avoid the escape of the molten metal in the event of a blowout. The equipment should be positioned at a convenient working height. Note that you will work with warm flasks, molten metal, and a burning torch. You don't want to twist into unpleasant and risky situations. Make every attempt to make this process as easy as possible.

Vacuum Casting Procedures

Here we explain the vacuum casting procesures. Otherwise, the processes for any technique are the same.

- Buy a wax pattern.

- If necessary, test the model and repair it.

- Check and mark the bases of rubber.

- On the base of the sprue mount tree wax.

- Mount the little sprue on the model, ideally not visible on the finished part in a position.

- Secure spruced tree model. Keep the sprue as short as feasible.

- Assemble the base flask and check your clearances.

- Take out the flask and weigh the base.

- Put the essential flask back together. Review your clearances.

- Instructions for investment mixing include investment. Put water in the mixing bowl of rubber.

- Put the jar over the bowl, turn it on.

- If you don't have enough mixed deposit to fill a bottle, pour it and mix more.

- Scratch the mark is identifying investments.

- Take out the rubber sprue using a twisting action.

- Discover the ways to keep the melted wax from the base of the oven before putting the bottles into the oven.

- Clean any dried deposits from outside of the flasks and mouth if you cast vacuum. In a cool oven, place the bottles.

- You should have containers with the weighted-out metal for each bottle.

- Switch off the oven at the end of the burnout cycle.

- River and the tumbler warm up.

- Place the hot flask in the centrifuge. For weigh, slide the crucible to the flask entrance.

- To check for lumps, use the stirring stick.

- Stop the torch and release the casting arm quickly after the metal has melted. Allow the machine to stop spinning until the bottle is removed.

- Move the flasks back and forth with tongs in the water pail. The castings are taken from the deposit by water. Wait a few minutes before you find castings. They will still be sparkling.

- You now have a lovely lump of metal covered in black oxidation and investment. Use a toothbrush to scour the castings to remove the maximum amount of investment.

- Strip casts and sprues from the tree. Also, remove the model sprues. Make sure the sprue area is clean. The cast components must be heated and wrapped. Pieces must be soldered, filed, and polished to finish.

- Finally, you've completed the task!

How to Calculate the Casting Metal Amount?

Metal requirement for mold filling = W x SGw x SGm + grams.

- W is the weight of wax or other modeling substance in grams.

- SGw stands for the particular gravity of wax or other modeling material.

- SGm represents the particular gravity of the metal utilized in the casting process.

Take Precautions When Learning Vacuum Casting

Your workshop will have temperatures high enough to destruct any material badly. Take the time to learn about the equipment, tools, and processes you are going to use. Your vacuum casting is not tough to perform. It has a learning curve, just like any new experience. Plan your equipment positioning and do a dry run of one or two until you trust the methods. Always keep a fire extinguisher near. When you cast indoors, it takes a lot of ventilation. Minimal ventilation is not sufficient. Both wax and torch gases are harmful. Keep your health and the health of others in mind.

Choosing the Gemstones

Develop your gemstone Passion with the Ultimate Gem Resource Whether you are a gemstone lover or work professionally with stones, the Alex machine buying guides are the basis for developing confidence in working with stones. Various gemstone-specific buying guidelines are available, ranging from sapphires and emeralds to rarer gemstones like pearls and chrysoprase. These specific materials include all of the gemological elements, the qualities of each gemstone, particular information, jeweler concerns, treatments to consider, factors that influence gem pricing, and much more. Lovely photo complements precise descriptions, allowing you to understand what is being presented fully.