What are Diamond Tools?

Diamond tools can be used for a variety of tasks, including cutting, grinding, and polishing.

What are Diamond Tools?

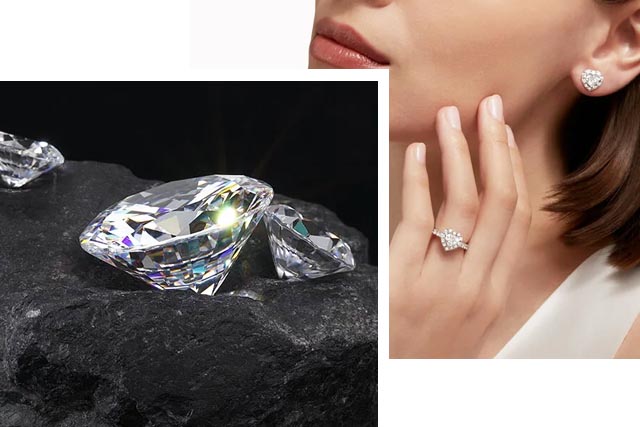

A diamond tool consists of a cutting edge, a support blade, and a drill tube. Diamonds can be found in some areas of the cutting edge. Only a small percentage of diamonds tools are made from natural or synthetically-produced diamonds that aren't suitable for jewelry. The tool must have high-quality diamonds and a high amount in each segment to work appropriately. Diamond blades, diamond drills, polycrystalline diamond (PCD) cutting tools, and diamond grinding tools are all examples of standard diamond instruments. Make sure you use the right tools for the right job at all times. Using an asphalt blade to cut concrete will result in a bond that is too strong for the material.

Note:Diamonds should not be used to cut steel because the carbon will dissolve into the workpiece, reducing tool life and work hardening.

Types of Diamond

There are 5 different types of diamonds:

- Type Ia –the most common.

- Type Ib –the second most common.

- Type 1aB –the third most common.

- Type IIa and IIb. In contrast to inclusions, an infrared analyzer is required to detect the atomic-level impurities within the crystalline lattice of carbon atoms.

A colorless diamond is ideal. These are the rarest diamonds. In fact, most diamonds have slight yellow or brown tints. Color is graded by the GIA from D (colorless) to Z. (colorful).

Usually, the grade difference is subtle. It's possible to create an eye-catching diamond with a visible tint (K+). Only N and higher diamonds have a shade. The hue deepens.

Colored diamonds are naturally occurring. These are the most popular colors and diamond types.

- Pink,

- Blue,

- Brown,

- Yellow,

- Orange,

- Green,

- Red

Most natural diamonds are yellow. White, blue, green, and red diamonds are rare types of diamonds.

Types of Diamond High Precision Tools

There are top-five diamond high-precision tools available. Take a look at our fantastic selection:

1. Reamer

When it comes to machining, Reamers are the best option because they guarantee excellent surface finish with small margins of error, high accuracy, and cost-effectiveness. Reamers have a significantly longer tool life than carbide reamers. It also has a high cutting angle, which shortens the cutting time and boosts productivity, leading to a higher volume of finished goods. One of the most appealing features of this cutting tool is its versatility in design.

2. Drill

The best thing about drills is how well they cut due to improved surface roughness and hole tolerance. As if that wasn't enough, Drills are ideally suited to cutting aerospace components and materials. Step Drills, in particular, are engineered to produce a clean cut in a shorter period.

3. Endmill

A high rake angle insert in the Endmill reduces burr formation for longer. As a result, they can produce larger quantities with greater efficiency by machining at a high cutting speed. This diamond tool also enhances the surface finish quality by doing so. As a result, Drills are an excellent choice for finishing non-ferrous metals and machining reinforced plastics.

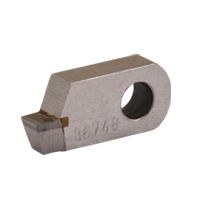

4. Boring Tools

Following that, boring tools are typically used to enlarge holes. By utilizing Boring Tools, they can achieve high precision while also delivering excellent finishing quality. Now, you can use boring tools to machine aluminum alloys, which is ideal for this application. To top it all off, it is preferable to use high rigidity equipment as well as a high precision holder to achieve the best possible machining results.

5. Forming Tools

Forming tools offer a solution that can reduce cycle time while increasing the complexity of workpiece shapes and sizes. Long tool life and complex forms combining copying and multi-stage designs contribute to increased productivity. Furthermore, the high quality of the surface finish produced by these industrial cutting tools cannot be overstated.

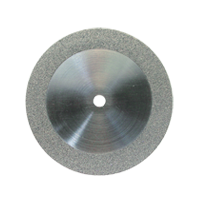

How Do Diamond Tools Work?

Diamond tools can remove material on a micro-scale. The metal bond does not wear away; rather, it "glazes over" the diamond, making it less effective. The diamond is therefore coated or covered as a result. Instead of the diamond, the metal bond is used as the cutting agent. You can use a diamond saw to cut anything from sapphire to granite to tile easily. For the diamond tool to keep cutting, the metal band surrounding the diamonds needs to wear away. It is critical to understand that for the diamond blade to cut effectively, both the diamond blade and the material must work cooperatively to achieve the best results. The diamond-type, quality, and grit size must be selected in accordance with the saw and the material being worked on. In addition, the bonding material must be compatible with the material to be cut. As a result, it is not possible to use a single blade to cut through all materials.

Flywheel and Posalux Tools

Flywheel:

Flexible machines can create bright designs on all types of jewelry.These are required when using these bits. So the high-speed handpiece is necessary for standard flex shaft machines.

Posalux tools:

Cuts with Posalux diamond tools are flawless. Diamond tools with concave and convex surfaces (making a bright uniform surface). Double-angle diamond tool multi-reflection They are all handmade in the old-world tradition by our diamond tools. They have several advantages over their less expensive counterparts. A loupe reveals an additional facetedbehind the cutting edge. The gold flakes can now fly away thanks to the additional facets. A brighter cut and a longer-lasting diamond are the results of this process. There are sharper, more precise (microscopically precise) cut angles in industrial diamonds when compared to less expensive tools.

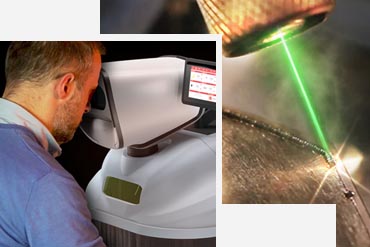

CNC VMC and Lathe Tools

Cutting-edge machines like CNC and VMC require advanced tools.Parts for modern technology can be made using this high-tech metalworking tool. CNCs can be found in various manufacturing processes, including lathes, milling machines, laser cutters, and many more. CNCs (computer numerically controlled machines) use computer logic to control the speed and metalwork.

Lathe tools:

We provide lathe tools in a variety of shapes and sizes, making them suitable for a variety of lathes. Furthermore, we tailor these to the specifications provided by our clients.

Chain and Ball Tools

Chain and ball, as the name suggests. Chain faceting machines are compatible with diamond cutting tools designed for chain machines.

- Chain faceting machines from Sisma, Ompar, Fasti, and others are compatible.

- a large selection of products for a variety of machines

- Customers from Italy, Turkey, India, China, and the rest of the world have come to depend on us for our extensive technical expertise.

- Carbide or PCD-based materials and tools; natural or mono-crystal diamonds; or a combination of these tools.

Background Tool

Alex has many unique and creative background tools, such as color engraving points and multiple diamonds points, to create new jewelry textures for the jewelry industry. Jewelry texture tools create new jewelry textures for rings, bracelets, and other jewelry items. Color texture engraver diamond mounted points come in various colors and sizes.

Diamond Cutting Tools

Diamond cutting tools are used to cut aluminum, brass, copper, graphite, wood, plastic, and carbon-fiber-reinforced polymer. The primary purposes of cutting tools areto achieve high abrasion resistance and hardness levels. Compared to conventional cutters, PCD diamond tools have a longer lifespan for the cutting element. These diamond tools also allow you to tailor your designs to your exact measurements.

Characteristics of Tool Material

Secure and reliable, high performance with efficiency in reducing mine waste and noise. As a cutting tool material, diamond performs exceptionally well in "hardness" and "heat diffusibility." Given its hardness, CBN is comparable to diamond in terms of hardness. However, CBN is primarily used for cutting ferrous metal due to its lower reactivity with ferrous metal than diamond.

- It has high stiffness, wear resistance, low friction, and high thermal conductivity.

- When heated, this material has a low coefficient of thermal expansion.

All Diamond Tools at Alex

When shopping for diamond tools, you have the option of selecting from a wide range of diamond tools based on diamond type, ensuring that you get everything you need and even more. Various tools and diamond accessories are available online, but how do we choose the best one? You should be familiar with the entire process of designing custom-made diamond jewelry. We have a large selection of diamond tool types ideal for jewelry making. Always check the quality of any product before using it. Don't settle for something you're not actually interested in. Don't settle for less than the best.

We'll keep our clients up to date on the latest competitive industry. Your performance in the jewelry finishing and processing industry will be enhanced by cutting-edge diamond tools. We make it possible for you to save a significant amount of money by offering a variety of options that are tailored to your specific needs and budget. You can place a bulk order if you need a large quantity of these items. At Alex, all diamond tools are eco-friendly and come with a slew of extras.