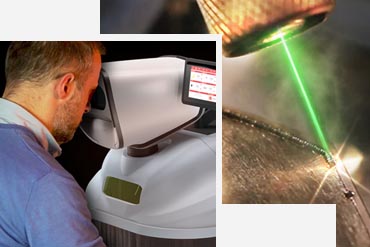

What is Laser Welding Machine | How to Use Laser Welding Machine

Alexmachine.com is the best place to find the most affordable laser welding machines. We provide you with the opportunity to get some of the best and most specific equipment types available at competitive prices at our online store. You can find a wide variety of jewelry laser welding machines here. The traditional welding process is sped up by these laser welding machines, providing unmatched precision. These tools are ideal for repairing anything that needs a lot of heat, and they're perfect for joining metals. Jewelry laser welding machines can be used in a variety of industries, including the jewelry industry, which requires a high level of precision.

What is Laser Welding Machine?

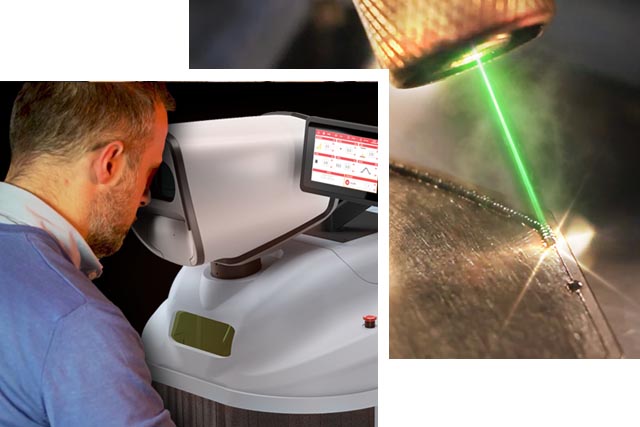

Laser welding is a non-contact method that uses a concentrated laser beam to assemble metallic components. This type of welding is ideal for applications requiring high speeds or low thermal distortion. In addition, the ability to precisely control welding quality during the process has made laser welding machines the preferred method for high-quality welding.

With the latest laser generation technologies, laser welding machines and laser welding technology are becoming increasingly common. A laser welding machine uses a laser beam to join metals or thermoplastics.

What Are the Available Laser Welding Machines Types?

There are various types of welding machinesused for laser welding in a wide range of industries. The manufacturing, medical, and jewelry industries are just a few examples. Some industries where laser welding technology has a significant impact can be found here.

1. A Jewelry Laser Welder Will Benefit Jewelers

Jewelry repair shops and manufacturers have more flexibility with laser welding machines. Jewelers can weld and solder jewelry items in ways that traditional solder/torch mechanisms would not allow. Because laser welding produces a fine, almost invisible weld, the finished product appears very clean, with a superior weld free of welding lines. Lasers are not limited to similar metals and can weld metals with different metallurgical properties together – for example, welding an 18K ring with platinum is no problem for a laser welder.

2. Industrial Laser Welder Applications.

Weld points and weld seams can be found in a variety of products, such as gearbox components and pacemakers. The versatility of laser welding machines allows them to be used in such applications as creating fine weld points as small as 1mm in diameter or deep welded seams as long as several meters. These machines generate slim seam geometries with minimal distortion and a high depth to width ratio. Lasers are capable of welding materials with high heat conductivity and melting temperatures. Because of the short controllable duration, it is possible to weld materials that would otherwise be impossible.

3. Dental Lab Laser Welder for High Precision Dental Prosthetics.

Laser welding tools are essential in today's dental laboratories. Laser welders are an excellent and convenient alternative to traditional soldering mechanisms for dental technicians in fabrication and reconstruction repair procedures such as loops and posts, cast extensions, and cast clasps. The free-moving concept of laser welding machines allows operators to use localized heat and accuracy to eliminate thermal expansion on dental prosthetics – such as implant bars and passive fit bridgework – and produce exceptional seam welds.

Click for laser welding machine and its types.

Laser Welding Machine for Jewelry Delivers Cleans Maintenance Welding

Laser welding jewelry is a viable alternative to traditional engraving methods such as chemical, mechanical, and stamping mechanisms. Laser welder systems are computer-controlled, environmentally friendly, and allow permanent non-contact abrasion-resistant engravings on all materials and precious stones. These advantages far outweigh the cost of the jewelry laser welder. Laser welding jewelry repair technology enables jewelers to perform complex repairs with extreme precision. Lasers cut through all metals, including precious stones, and provide excellent cutting quality and delicate designs to jewelry repairers.

Equipment of Laser Welding Machine

There are all commonly used equipment of laser welding machinesby welders to clean or burn the skin metal surfaces leading up to welding.

- C-clamps,

- wire brushes,

- needle nose pliers,

- flint strikers,

- needle-nose

- linesman cutting pliers

- electrode tip cleaners.

You'll need a welder, electrode feeds, and safety gear to learn welding basics. Consider taking a class or finding an instructor who will first show you the ropes. Basic safety equipment can result in severe injury or eye damage if you don't know what they are. When two metal parts are joined together, they are melted together to form a weld.

Advantages and Disadvantages of Laser Welding

There are many advantages to laser welding over more traditional forms of welding. Laser welding machines have several benefits, such as the following.

Advantages:

- Laser welding machines are beneficial in a variety of ways. The speed of a laser welding machine is the most significant advantage.

- Automation and Computer-Aided Systems make it easier to integrate laser welding. There is a significant improvement in both accuracy and efficiency due to this.

- During the welding process, the tools are not damaged in any way.

- The laser beams’ focus is extremely precise. Because of this, the weld will last for a long time.

- The welding process is significantly faster than that of traditional methods. This allows laser welding to be used in large-scale manufacturing.

- Laser welding can be used to manufacture medical industry products that require a high degree of precision.

- Compared to other welding techniques, the amount of energy required is significantly less.

- After welding, there is no need for additional finishing of the product. Consequently, the welding time and manpower are saved.

- The method is non-contact. However, the finished product will be of higher quality, and the machines will last longer because there will be no contacting parts.

Disadvantages:

- It is expensive to purchase welding machines, and the cost varies depending on the equipment.

- Due to the limited amount of material produced, filler materials are expensive. Welding time is short compared to material consumption, and there are few after-welding operations, so this disadvantage is minimized.

Application of Laser Beam Machine

Laser welding has a wide range of applications in a variety of industries. Manufacturing, medical, and jewelry manufacturing are among the industries represented. An important application of laser process technology is the laser spot welder. Using thermal conduction, the laser radiation heats the work piece's surface, which then radiates heat into the work piece's interior via thermal conduction, melting the work piece and forming a specific molten pool. It is widely used in the production of gold and silver jewelry and the welding of miniature and small parts because of its unique advantages.

A wide range of industries can benefit from the laser's versatility in meeting a wide range of materials, including:

Crafted from a single billet of (also stainless steel)

- Aluminum

- Silver

- Gold

- Copper

- Bronze

- Nickel

- Titanium

- Platinum

- Palladium

There are multiple industries where a laser welding machine can be used profitably, from goldsmiths to the automotive industry and many others in between. Also used frequently in aviation and aerospace and sporting goods and jewelry, including golf clubs, watches, gold and silver jewelry, medical devices and dentures made of titanium alloy, electronic devices, and automobiles. A gold laser welding machine for the jewelry industry.

Characteristics of Laser Beam Welding

- With a wide range of settings available, welders can achieve a wide range of welding effects. The control rod in the sealed cavity is used to make quick and easy adjustments to the parameters.

- The use of ergonomic principles to create a unique design.

- Automated light-shielding systems are used to prevent eye irritation during operation.

- This type of weld is fast and efficient with little distortion and a small affected area. Welding points are pollution-free and energy-efficient.

Welding quality must meet the following requirements to produce high-quality products:

- It was found that the bead had no flaws.

- There are no irregularities in the bead's shape, width, or height.

- The final product is accurate in terms of size and distortion.

- The welds are strong enough to meet the specifications.

- Full penetration welds, which join the complete interface between the base materials, should never be compromised in favor of partial penetration welds.

Laser Welding Machine Types

There is a wide range of laser welding machines available that are simple to use and can help you weld your piece very efficiently. Take a look at our incredible selection:

- Laser Welding Machine MS 35

- Laser Welding Machine Master

- Laser Welding Machine Mega

- Laser Welding Machine Mega Hit

- Dado Laser Welder

- Dado Laser Welder with Argon Connection

- Laser Welding Machine Master S Microscope

- Laser Welding Machine Master S 3D

- Laser Welding Machine Mega Hit Microscope

- Laser Welding Machine Mega Hit 3D

- Laser Welding Machine Mega Silver Microscope

- Laser Welding Machine Mega Silver 3D

For further details, visit our online store.

Laser Welding Machine Prices

What is the cost of a laser welding machine? It's a popular question among skilled artisans, especially those new to the industry. The price of these welding machinesis determined by several things. These factors include product type,quality, substance, and purchase location. The price of a laser machine can vary greatly depending on product types. However, you may be able to find the most incredible productat a reasonable cost. On the other hand, getting the best laser welding machine should not be an excuse to bankrupt.

So, you're looking for laser welder kit plans, or have an idea for a cheaplaser welding machine for small, densely arranged, precise, and heat-sensitive parts with jewelry, kitchenware, and other industries in the jewelry and kitchenware industries, aerospace, and automotive components, commercial and shipbuilding, chemical and medical industries to realize spot welding and stitch welding, as well as sealing welding. As a customer, you will likely be able to choose a piece of high-quality material that meets your melting requirements while remaining within your budget. This is feasible if you have the expert guidance and the right place to buy.

For further pricing details, please visit our online store.

Alex has all of the additionallaser machines you require. We have everything from welding machines to Laser welding machine mega silver 3D at our store. We have whatever you're looking for.

FAQ:

What can a laser welder weld?

Welding carbon steel, silver, aluminum, and titanium is possible with laser welding because of its flexibility. Welding high-carbon steel raises the possibility of cracking because of the rapid cooling during the welding process. In comparison to electron beam welding, the weld quality is excellent.

What is the advantage of laser welding?

The area affected by the heat is limited, and there is no distortion in the space around the welding area due to rapid cooling. Laser welded components experience very little or no deformation and shrinkage. Laser welders can weld stainless steel, aluminum, titanium, high-strength steel, dissimilar materials, and precious metals together. The laser beam can be further divided into several beams for greater precision. This enables perfect accuracy in the welding of small parts.

Is laser welding good?

Yes, it's an excellent option for arc welding, and it often beats welding processes because of its concentrated beam, which minimizes thermal effects. Laser welding can accomplish soldering tasks that traditional welding methods cannot.

Is laser welding as strong as MIG?

In comparison to traditional welding, the laser's ability to penetrate deep into the material increases its benefits. Laser welding is three to ten times faster than MIG when it comes to thick joints that would otherwise require multiple passes.

Where is laser welding used?

Laser welding is used in a variety of industries, most notably the jewelry, automotive, and dental reconstruction industries.

Is laser welding as strong as TIG welding?

Compared to TIG, the laser can weld relatively thick joints requiring multiple passes with TIG, allowing it to be up to ten times faster. Laser welding produces faster welds, especially with modern high-power continuous wave (CW) fiber lasers.