Silver Engraving Guide For Jeweler's | Costs and Steps

Engraving is a simple and quick process that adds value to the jewelry. Jewelers can engrave their pieces using a variety of techniques. Understanding engraving and its processes can help you determine which option is best for the pieces you create. This basic guide will explain what engraving is, the various types and tools of silver engraving, and the various materials engraved. Check out our grand collection of engraving tools.

What is Silver Engraving?

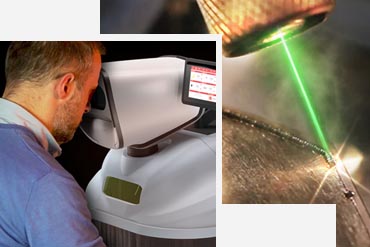

Sterling silver is one of the most valued metals in history and still today. The laser can easily engrave, stamp, carve or cut silver sterling in seconds.

Silver engraving is one of the most ancient and important printing techniques. It is the practice of cutting grooves with a burin to insightful design on a hard, generally flat surface.

The result may be a;

- The decorated object itself, for the engraved of silver,

- Printing on paper of images as prints and pictures,

- Supply of intaglio printing sheets of copper or other metal also referred to as "engravings."

How to Engrave by Hand?

Hand engraving is done with shaped steel cutters with sharpened edges mounted in a wooden handle. The cutters themselves come in extra-long lengths that can be cut down to fit the person using them. The tang (pointed handle end) is not as hard as the tool itself and is meant to be snapped off to make the ideal design. The rough end should be ground down and added into a wooden handle to prepare hand engraving.

What is Jewelry Engraving?

In contrast to etching, engraving leaves a much deeper incision. The soft metal sheet is engraved with a burin tool to create a design

The term "engraving" can be defined in two ways:

- An engraving is a cut-out image or design on a surface.

- An engraving is an image printed from a plate with designs cut into it.

The History of Jewelry Engraving

Engraving techniques date back to the Middle Stone Ages or around 60,000 BC. Following that, engravings on bones, ivory, and rocks dating from the same era were commonly discovered. Engraving evolved and became a profession. As a result, it has long been used in decoration, particularly metallic ornaments. Furthermore, artists used various engraving techniques to decorate metalwork, such as swords, shields, and armors. Initially, engraving was used to create permanent cast-dyes, which were later used to create printed decorative. However, engraving techniques evolved and became widely used to decorate metallic ornaments such as jewelry by carving patterns, adding texture, and increasing their value.

The demand for engraving metallic ornaments such as gold jewelry has increased. One major reason for this is that people want to wear personalized jewelry with their names engraved. Furthermore, it has become a regulatory requirement for vendors to mark their jewelry with specific serials and numbers to identify them.

Engraving Methods and Techniques

Machines are used to secure work, while silver engraving is just as important as the engravers themselves. It is difficult to understand. If the workpiece slides across the bank, it will also be difficult to use an expertly sharpened graver in your experienced hands. It is no wonder that many tools have been developed to support cutting work.

1. Working With the Graver

Professional gravers will almost certainly be given elaborate designs or long text panels, but a single or decorative line is useful to be cut on the bank. Moreover, goldsmiths who trust in their ability to grave will seek a graver to help clean up the rooms, sharpen the details, and cut stones into seats.

Note: Every culture that made precious metals invented an instrument for silver engraving or comparable cutting.

Regular work with gravers, however, when you keep to it, teaches subtle factors such as angle, strength, and roll. Practicing for 15 minutes each day is better than working for a few hours once a month. If the engraver is sharpened properly, even hard metal slides relatively easily. If you use brute force to drive the tool, something is wrong, and it probably needs to be reformed.

2. Engine Turning

This method can be seen as an engraving by using a sharpened steel tool to cut small metal bits to create decorative patterns. The basic difference is that a machine set up to produce regular, often repetitive strokes guide the work under the tool. Motor (engine) turning was developed during the middle of the last century as part of industrializing jewelry production, but now other more straight methods are being replaced. The technique can be used for carving forms, e.g., plastic or ivory, but it will be decoratively used on flat surfaces. This technique is ideal for decorative boxes, watch cases, writing tools, medallions, and the like because the decorated surfaces wear better than smooth surfaces. Indeed, on engine-turned surfaces, transparent enamels appear very precious.

3. Machine Engraving

Engravers cut the design into the surface, most commonly a copper plate, with a hardened steel tool called a burin or graver. Besides hand graving, graving equipment is not controlled directly by hand and requires less human finesse. Although traditional gravure has received little attention in the modern days, considerable efforts have been made to develop the machine gravure. In x, y, and z axes, a tool is guided by a computer in the CAD/computer-aided design process, which allows the development of image formats created on a computer screen.

What is Hand Engraving?

Hand engraving is an ancient art form in which artwork is created using only a small steel graver. The engraver is pushed through the metal with the hand, no machinery is used.

How to engrave at home using hand engraving tools?

Jewelry engraving designs can be printed directly onto metal or transferred using a variety of methods. As you begin to trace your first line, use even pressure to push your hand engraving tool down and forward. The process is repeated until each cut reaches the required depth.

When learning how to engrave metal by hand, your hand engraving tools should be held at an angle that is neither too deep nor too shallow, but only experience and practice will help you. There is a wide variety of tools available for jewelry engraving. For beginners, it is best to start with simpler jewelry tools, such as a v-shaped graver or a knife graver.

Different Types of Hand Engraving Tools

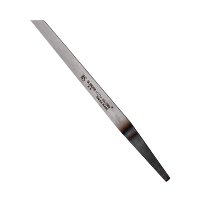

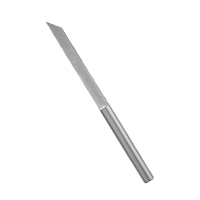

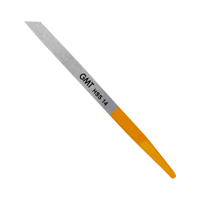

Here are some steel hand engraving tools that you can use:

- Scraper – A tool used to clean the metal surface by scraping it away.

- Spit stick – A tool for cutting fluid lines.

- Scorper – A tool used to cut and carve away larger metal areas. It is available in various profiles, including flat, round edge, oval, and others, each of which produces a shaped cut.

- Graver – A tool used to cut metal lines that swell or shrink depending on the angle used. Used in stone setting and jewelry engraving, and available in various profiles, including the knife, chisel, square, diamond, flat edge, round edge, oval, and so on.

Mechanical Engraving Tools

To achieve fine detail on flat surfaces, steel burrs can be used in a rotary drill, pendant motor, or micro-motor. They're especially useful for glass engraving and softer metals like gold and silver. Check out our burrs guide to learn how to use various types of burrs and more. Are you ready to take a good start at making your own engraved jewelry designs? We have everything you need at Alex Machine for precise silver engraving. It can be used to add unique and intricate engravings to your jewelry-making projects.

Browse our selection of hand and electric engraving tools online today.

Engraving Tools

Engravers cut the design into the surface, most commonly a copper plate, with a hardened steel tool called a burin or graver. The best silver engraving tools enable you to engrave on a surface like metal, wood, plastic, glass, stone, ceramic, etc., easy and accurate. You could engrave your name, someone's name, animal, flower, whatever you want.

These tools are usually powered by batteries to run the small motor, which rotates the bit.

We have listed the top 7 silver engraving tools. Follow the links below for more information.

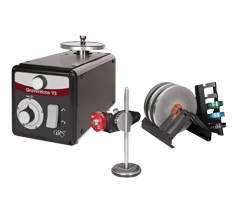

1. Vallorbe Engravers

2. Grobet Engravers

3. Engraving Machines

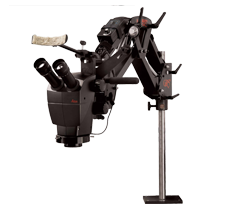

4. Engraving Blocks Tools

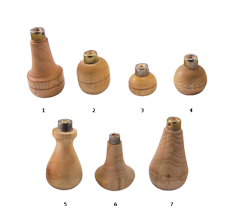

5. Handles

6. Pushers and Scrapers

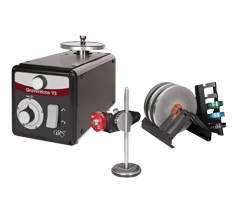

7. Grs Products

Engraving Costs:

Our silver engraving services are extremely popular with people worldwide who have jewelry items that require a personal touch. We've seen it all, from

- Ring bands

- Pendants

- Watch cases

- Bracelets

- Neckless/pendants

- Cufflinks

- Trophies

Many of these customers have carefully considered what they want their jewelry or watches to say and what they mean. However, since many of these customers are not familiar with the engraving process, additional considerations are often required before registration. Before your jewelry is engraved, here are five things to consider:

1. What do you want the engraving to say?

Do you want to remember a specific date or phrase for the rest of your life? Maybe you'd like a short message, such as "I love you," or a significant date roman numerals in your life. For financial reasons, many people prefer to have their marriage rings engraved. If you and your partner have your marriage rings engraved, you should decide if you would like to have the same registration. Some partners prefer this, whereas others prefer a personalized one. We can now engrave emoji into your items – whatever you want, our expert designers can do it.

2. How big is the piece you want to be engraved?

The jewelry item's size determines how many letters or numbers can fit and how small the engraving should be. Thin bands often lead to smaller characters, while larger objects can contain more information. In most cases, the entries range between 1 and 16 letters. But that's not a rule. Please reach us for more information if you have a longer registration. Our engravers offer two choices regarding fonts: block or script. Take both options carefully to see if you want to.

3. What would you like to engrave?

We engrave all kinds of jewelry, but the most popular are rings, bracelets, and necklaces. Rings can be graved inside the band, although some people prefer the less common band engraved on the outside. Besides roman numeral or text, some people develop creative and attractive ideas, like having a fingerprint for a special person. There is more room for creativity when it comes to bracelets. For instance, charms can be engraved with initials.

You may have the bracelet band graved with a quote or a saying that means something for you if you prefer to stick to the tradition. Pendants necklace can also be engraved with actual photographs. This gives engraving a totally new, customized look.

4. How much?

Although many engravings will cost only $30 plus shipping to anywhere in the country. It fluctuates with the material or metal engraved and the number of characters, but $30 covers most jobs. You can find out more about our online engraving services to learn more about the price.

5. How long does it take to get my jewelry engraved?

There is no time for every piece of jewelry to be engraved; several factors include material, inscription length, size of the jewelry, etc. It may take hours or less, but more complex parts or engravings may take longer. Communicate with your jeweler for a more precise timeframe. However, fast repairs have a turn of one day differently based on complex jewelry. Silver engraving is one of the most important choices about your jewelry you can make. Call us or get some advice from the Alex jewelry repairs team today if you need help or decide exactly what you are looking for.

Please confirm what you want to engraved or fit your favorite piece? Visit our engraving page for what we can do for you.