Soldering Chemicals for Jewelry Making - Types, Uses, and Safety

Choose high-quality soldering chemicals for jewelry making to create stunning, long-lasting pieces. Our online store offers the best pricing on a wide range of high-quality products. Shop now!

Types of Soldering Chemicals for Jewelry Making

Soldering metal components in jewelry is frequent. This procedure uses multiple soldering chemicals. The jewelry project and metal type determine the soldering chemical. Jewelry-making soldering chemicals include:

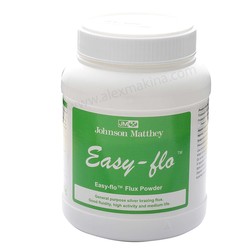

1. Fluxes and Flux Pens

Flux cleans metal surfaces before soldering. It ensures a clean, oxide-free surface for strong solder joints. Metals oxidize during soldering, generating a thin oxide coating. This oxide coating hinders solder adhesion, weakening junctions. Fluxes remove or prevent this oxide layer, making solder flow easier and establishing a solid bond.

Flux pens make applying flux to specific jewelry sections easy. They are useful for detailed designs and for avoiding flux on other jewelry elements. After soldering, the flux should be wiped off to prevent corrosion.

2. Soldering Pastes and Creams

Soldering pastes and creams are paste-like mixtures of flux and solder. They are pre-mixed formulas that provide convenience and ease of use. Because they eliminate the need for separate flux treatment and solder installation, these devices are extremely popular among jewelry producers. When using soldering paste or cream, apply it directly to the joint or region to be soldered. The flux in the paste cleans the metal surface when heated, and the solder pours into the joint to form a bond. Many solder compositions are available in soldering pastes and creams, such as hard, medium, and easy solder, each having a distinct melting point for different soldering operations.

3. Pickling Solutions

After soldering, pickling solutions remove flux residues, oxides, and fire scale. Fire scale occurs on metals when heated. Acidic pickling solutions remove these residues, leaving the jewelry clean and ready for finishing or polishing. Jewelry makers make pickling baths with diluted pickling ingredients and water. The jewelry piece is pickled for a short period after soldering, depending on the solution's strength and the metals employed. Due to its acidity, pickling solutions must be handled safely. These 3 soldering chemicals ensure clean, sturdy, and attractive solder joins and jewelry. For the greatest jewelry soldering results, use them appropriately and safely.

Uses of Soldering Chemicals in Jewelry Making

Soldering chemicals are essential for jewelry creation with gold, silver, copper, and brass. Solder joins metal pieces. Soldering chemicals clean, prepare, and bond metals for a clean, professional finish. Jewelry soldering chemicals include:

· Ensuring Clean and Oxide-Free Surfaces

To produce a strong and stable bond, clean and oxide-free metal surfaces are required before soldering. When exposed to air, metals such as silver, copper, and brass acquire oxides on their surfaces, which can impair the ability of the solder to flow and adhere effectively. Flux is a typical soldering chemical that is used to solve this problem. Flux is applied to metal surfaces before soldering to eliminate existing oxides and prevent new ones from forming during the soldering process. It provides a clean and chemically receptive surface, allowing the solder to form strong molecular connections with the metal.

· Facilitating Solder Flow and Adhesion

Solder is a metal alloy with a low melting point, designed to flow and bond with metal surfaces when heated. However, it needs assistance in flowing and adhering to the intended joints. Flux not only helps clean the surfaces but also facilitates the flow of solder by reducing the surface tension of the molten solder. This makes it easier for the solder to spread and fill gaps between the metal components, ensuring a tight and secure bond. Without the use of flux or similar soldering chemicals, the solder may bead up or not flow properly, resulting in weak or incomplete joints.

· Removing Oxidation and Soldering Residues

Oxidation and flux residues on metal surfaces may damage jewelry's appearance and durability. Jewelers employ pickle solutions or compounds to clean and polish their products. Pickling solutions frequently contain sulfuric or citric acid. They remove soldering residues, oxides, and other contaminants from metal surfaces. Immersing the soldered piece in pickle solution removes these undesirable substances, leaving the jewelry clean, bright, and ready for polishing or patination.

Importance of Safety in Soldering Processes

· Proper Ventilation and Fume Extraction

Soldering involves the use of flux and solder, which can release harmful fumes, such as volatile organic compounds (VOCs) and metal oxides, if not properly managed. Adequate ventilation and fume extraction systems are crucial to prevent inhalation of these hazardous substances, protecting the health of the soldering operators and anyone nearby.

· Use of Personal Protective Equipment (PPE)

Soldering operations expose workers to potential risks, including burns, eye injuries, and skin irritation. Accidents and injuries can be prevented by using personal protective equipment, such as safety goggles, heat-resistant gloves, and protective clothes.

· Handling and Storage Precautions

Solder may include lead or other toxic materials that can cause injury if consumed or touched directly. Proper handling and storage practices are necessary to prevent accidental exposure and to keep the solder and related materials out of reach of children or unauthorized personnel.

Why Choose Alex Machine Soldering Chemicals for Jewelry Making?

When choosing jewelry-making chemicals, looking at standards such as quality, durability, and compatibility for the specific tasks involved is important. Alex Machine is a popular choice for soldering chemicals for several reasons:

· High-Quality Formulations

Alex Machine Soldering Chemicals are known for their exceptional quality, crafted with precision to ensure optimal performance during jewelry making. Their formulations are designed to create strong and reliable bonds, making the soldering process efficient and effective.

· Trusted Reputation

Alex Machine has built a reputation as a reliable and reputable supplier of soldering chemicals for jewelry making. Jewelers and craftsmen worldwide trust their products for their consistent results and ease of use, making them a preferred choice in the industry.

· Comprehensive Range

Alex Machine offers a comprehensive range of soldering chemicals tailored to various jewelry-making needs. Whether it's fluxes, solder pastes, or specialized solutions, their diverse product lineup caters to different metals and soldering techniques, providing jewelers with versatile options for their projects.