Carving Wax Types and Equipment

The beauty of carving wax for casting is that you can start with as few or as many wax carving tools as you like and still create something unique and completelyhandmade. Once you haveaccurately shaped and filed a block of wax into the beginnings of a jewelry design, there's nothing quite as sufficient as seeing your designs take shape in the casting process. To help you get started, here are some of the wax carving tools you will need.

Wax Working Equipment and Wax Carving Tools

According to the project requirements you have decided to start with, you will need to know whether your project will require wax blocks or wax tubes.

1. Wax Carving Kits

For accuracy carving and an infinite number of shaping tricks and techniques, you'll need to pick up a wax carver set. This can include several hand carving tools with pointed, flat, and rounded edges to help you precisely shape your wax. There are multiple wax carving tool sets to choose from, so make sure that you choose the one that best suits your work and your budget. You will need to experiment to get a better idea of exactly what works for you. So if possible, borrow from a friend or coworker until you figure out which types of wax carving tools suit you.

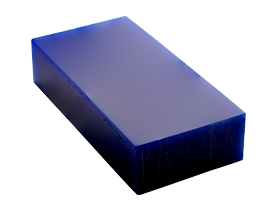

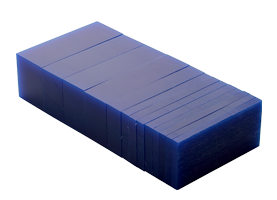

2. Carving Wax Blocks

Wax blocks are easily sawed, carved, drilled, or milled and can even be turned on a lathe. Wax blocks burn out cleanly from molds, are highly flexible, and can be used for creating extremely thin wall sections.

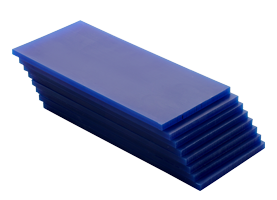

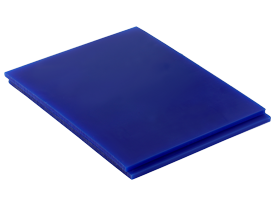

3. Wax Sheets

Wax sheets are best used to form a raised design of no more than a few millimeters. Most wax sheets are easily pliable at room temperature, making it simple to apply drawings and cut and file away, leaving behind a raised relief that you can add to pendants, brooches, or earrings. The best thing about using wax sheets is that you can be incredibly accurate even with the smallest designs.

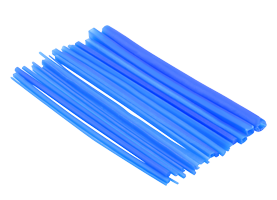

4. Wax Wires

If you're experimenting with layering wax onto your design for more of a three-dimensional effect, you can also use wax wires. These tend to come in assorted sizes and shapes and can be molded to create decorative elements on rings or settings to complement a stone you're using. They can even be used to simply add more height to the wax sheet that you're working with too.

How to use Carving Waxes?

Therefore, you want to carve wax andsee some wax carving? But you are unsure what wax to get, where to buy it, and how to carve it? These waxes in various sizes and designs, from sheets to blocks bored-out ring spaces. so we are providing various kinds of carving wax. However, it may, and the genuine difference in the shade of the wax. Alex Machine is a standard industry (however, here is the best brand that observes the overall principle; it's more consideration of what shading implies. Our carving wax is accessible with huge formulations to oblige your greatest scope of design needs. It can be easily carved, utilized, cut, and even machined to repeat the most unpredictable design subtleties. To encourage the design cycle, these are accessible in a wide range of shapes and structures.

Here we provide some using tips;

- Calipers are cast-off to measure where the cut should be made to accommodate both the piece's finished size and added space for shaping.

- The block is cut utilizing a jeweler specialist's saw.

- A wide-faced file is utilized to generally measure the cut bit of Wax into the overall shape of the completed piece.

- Calipers are utilized to twofold check the general components of the generally molded piece.

- The completed design should be possible, utilizing a wide range of intensity or hand-worked molding and carving tools.

- A wire wax is attached to the finished wax design to prepare the piece to make a model.

Shaping and carvingwax is very satisfying. You can start with the most basic tools.

Choosing the Best Option

Here You will see the high-quality and different colors with unique shapes. Pick the best carving wax options, whatever you want, and see the below list and choose the best one you need, visitnow!

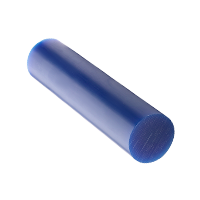

1. Matt Wax Tube Solid

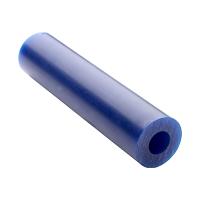

2. Matt Wax Tube Center Hole

3. Matt Yüzük Mumu İçi Boş Kaçık

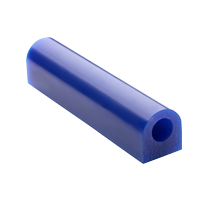

4. Matt Wax Tube Flat Top

5. Matt Wax Bar

6. Matt Slices Wax Bar

7. Matt Smooth Slices Bars

8. Matt Smooth Slices Bar Mix Size

9. Matt Tablet Wax 5 mm

10. Matt Bracelet Wax

11. Matt Gun Wax

12. Ferris Casting Wax Sheet

13. Ferris Wax Wires spool

14. Ferris Wax Wires Assortments

15. Ferris Sprue Wax

17. Ferris Cowdery Assortment Wax

It has been proven that they are very popular and jewelry makers all over the world have liked them and bought them from Alex. Machine.