Induction Melting Furnaces Products

Induction melting furnaces are used in a range of industries including the heavy industry, jewelry industry, and the dental industry for casting purposes and to melt metal. Any metal can be used in the furnace as long as it is electrically conductive. This allows the application of electromagnetic waves that can be applied indirectly using a graphite crucible, or directly with a ceramic crucible.

After the alloy is melted, the molten metal is injected to a casting flash or centrifugally spun in order to make the part to be cast.

Benefits of An Induction Melting Furnace

An induction melting furnace offers a range of advantages over conventional casting methods. A major disadvantage of conventional resistance melting or flame casting is that it has continuously changing characteristics so this makes it difficult to make products that are identical. On the other hand, an induction melting furnace can deliver consistent results regularly. There is high repeatability and users can expect constant results for extended periods of time. Moreover, the heat produced by an induction melting furnace is accurate and speedy. This heat can be created as soon as the material allows – hence reducing the soak time.

What Is An Induction Furnace?

A key benefit of an induction furnace is that it delivers an energy-efficient, clean method for melting. Quite importantly, it is an easily controllable system in comparison to other methods of melting metal. Because the induction melting process does not use an arc or combustion, the temperature of the furnace is not higher than the melting temperature of that particular metal. The ability to precisely control the temperature ensures valuable alloying elements are not lost during the melting procedure. Today in the 21st century, more and more jewelry makers are opting for an induction melting furnace due to its efficiency and reliable results.

What is A Melting Furnace?

A melting furnace is used to heat solid materials beyond the melting point to liquidity said materials. Thermal processing equipment is used to evaluate the temperature and ensure internal characteristics are changed to the required state.

What is an Induction Melting Machine?

An induction melting machine is a proven and reliable method of melting glass and metal. It can work in a range of operations including precious metals, investment casting, lab applications, and tilting furnace melting. A good induction melting machine can melt both ferrous and non-ferrous metals and even dental alloys and nuclear material.

During the process of induction heating in an induction melting machine, the current-carrying coil exposes the metal to an alternating electromagnetic field. This is a completely contact-free process where the material forms eddy currents that produce heat (due to the eddy currents). This process can be accurately controlled by changing the power and frequency. Another benefit of an induction melting machine is that the electromagnetic forces create intensive motion that then results in the perfect blending of the melted metals.

What is a Mini Induction Furnace?

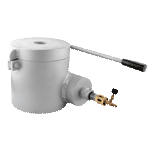

A mini induction furnace is a small capacity furnace that is developed to meet the requirements of processes like investment casting. These furnaces are built with durable rigid materials that can provide high structural strength to the furnace while keeping weight to a minimum – both of these are crucial features to a furnace that is expected to be moved and poured by manual labour and not machines. Certain types of mini induction furnaces have aluminium alloy sides and rugged ceramic tops to reduce weight further.

The durable frame and construction ensure that these furnaces have a long lifespan and are able to operate at high frequencies thus maximizing efficiency at the workshop. These mini induction furnaces can be used in lab operations, precious metal refining and casting, small run casting, prototype casting, or any other instance where smaller levels of molten metal are required.

What Is A 10 kg Induction Furnace?

A 10 kg induction furnace can be used to melt just about any metal one has in mind. They can process both ferrous and non-ferrous metals including lead, silver, and gold in very little time. The weight signified on the machine name indicates the weight of the metal it can accommodate – in this case, it is 10 kg.

Metal Melting Furnace

A key highlight of a metal melting furnace is the ability to handle a range of quantities (up to the specified weight) and the types of materials. A metal melting furnace could melt up to 250 kilograms of metal in one operation and about 1 kilogram in the next for a smaller application.

Electric Melting Furnace

The term electric melting furnace is another name for an induction melting furnace. İn the commercial industry, induction melting furnace is the more frequently used term however, many new to the industry may refer to the system as an electric melting furnace. Technically, both are correct.

What is an induction melting furnace?

An electrical furnace where the metal is heated through induction heating is known as an induction melting furnace. These forms of melting furnaces are quickly replacing traditional systems that are in place.

What are the benefits and drawbacks of an induction furnace?

When compared to traditional modes of metal melting, an induction furnace is clean and energy efficient. İt is also very simple to control the melting process every precisely. Induction furnaces have one major drawback and that is that they don't have any refining capacity. Charge materials should be of known composition and free of oxidation products. Additionally, there is a chance that some alloying elements could be lost due to the oxidation process. They will need to be added again to the melt.

How does an induction melting furnace work?

İnduction furnaces work by the use of a low voltage, high current that is induced in the metal or secondary coil by a high voltage electrical source which is taken from a primary coil. İn simpler terms, induction heating is just a process that transfers heat energy.

What can you melt in an induction melting furnace?

An induction melting furnace is used to melt a range of materials including precious metals, aluminium, and copper to name a few.