Jewelry Burs

With Alex Makina’s wide selection of burr tools, the task of shaping a jewelry piece’s design is made much easier. To easily craft the metal on to which a stone will be set, view our selection today andyou can develop professional designs in half the time.

What are jewelry burs?

Jewelry burs are used in the jewelry business to remove excess materials like metal in situations where extreme precision is important. Jewelry burs come in a range of shapes and cuts. Most of the time, jewelry burs are suited for a specific job but may sometimes accommodate a few other tasks. These burs are made using highly durable metals which can withstand the high pressures experienced when removing metal for stone setting. They are used in the same way that a craftsman would use a flex shaft rotary precision motor or a dremmel. However, jewelry burs can be customized for every job.

For example, if it is a bezel setting that you are looking to create, a round bur would be a good choice. If you want to undercut prongs to set a diamond, a 90 degree or 45 degree bur is perfect for it.

For a marquise setting or square setting, a heart shaped tool can be used. With an exhausting range of jewelry burs to choose from, you can find a jewelry bur for any setting work you have. Here are some of the more popular jewelry burs used today.

Setting burr

These jewelry burs have straight sides and a pointy tip. They are used to drill and create seats for a stone to be set.

Bearing cutter

It is similar to the former but has tampered sides. The jewelry burs are used to remove metals and cut grooves to seat stones.

Ball burr

Spherical and used to create rounded indentations for a stone. Sometimes used for general shaping too.

Bud burr

Used to cut round shapes for stones but also has another pointed tip for precise work.

Flame burr

Used for creating fine detail. Thanks to an elongated narrow shape, it can be used inside a setting.

Cup burr

These burrs are usually utilized to finish the tips of grains or claws. They come with a spherical, concave cutting surface that allows the craftsman to create a neatly rounded shape.

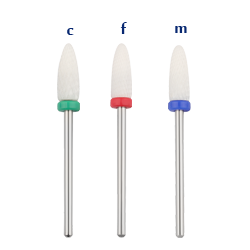

Cone burs

These burs come with a tapered cutting surface. Cone burs are well suited for widening a pilot hole, removing metal precisely, and any detailing work.

What jewelry tools should you use a bur with?

Burs work at their best when combined with jewelry tools like a pendant motor. This is because it can help hasten the time needed to remove metal. If precision is important or you want to work with your hand, a jewelry bur can be combined with a pin vice for good results

How to store burrs with jewelry supplies?

You must not just dump in your burs with the rest of your jewelry supplies. It is recommended that you store burrs in an upright position. For example, you could place them on a rack but do ensure that the burrs are not touching each other.

How to maintain burrs and stone setting tools

Regardless of the metal that you will be using a bur or other stone setting tool on, it is important to always keep them rust free and sharp. This can be done with a good lubricant- thiscan reduce chatter and friction, delivering better results andensuring your tools last longer.

Choosing the right burs

Finding the right bur can be an overwhelming task because they range in their dozens. You will find burs of numerous materials, head shapes, brands, and configurations – and all of them will have tens of different sizes.

The materials used for making burs are generally the following three:

- Carbide Steel: Used for high speed tasks, it maintains sharp edges and lasts the longest. It is also more expensive.

- High speed steel: Hits the right balance between durability and cost. Maintains the hardness at high speeds too.

- Vanadium Steel: Offers precise cutting and is the cheapest. Best for low speeds but wears quickly.

The reason there are many head shapes is that there is a range of tasks that can be completed with each style. A craftsman could use 4 different head shapes to finish a single task. On theother hand, another craftsman could use one ball bur to finish an array of tasks.

Some of the most common jobs include:

- Engraving

- Filing

- Deburring

- Drilling

- Wax carving

- Stonesetting

Jewelry tools wholesale

Buying Jewelry tools wholesale can help a craftsman find better deals on his favored products. If you are looking to equip a workplace with modern tools, it is best that you look for wholesale deals.